In today’s rapidly advancing industrial and technological landscape, electro mechanical assembly plays a crucial role in bridging the gap between electronic components and mechanical systems. It involves integrating circuit boards, wiring, enclosures, and moving parts into a fully functional unit that performs precise operations. From medical devices and automotive systems to industrial control panels and aerospace instruments, electro mechanical assemblies form the backbone of countless applications where accuracy, reliability, and efficiency are essential.

What Is Electro Mechanical Assembly?

Electro mechanical assembly refers to the process of combining electrical and mechanical elements into one cohesive product. This typically includes assembling printed circuit boards (PCBs), wiring harnesses, sensors, motors, switches, and mechanical enclosures. The goal is to create a complete device or subsystem capable of performing complex functions through the seamless interaction between electronic controls and mechanical movement.

In industries such as aerospace, telecommunications, and defense, these assemblies are essential for equipment that demands high reliability, performance, and durability. Every component must fit and function perfectly, making precision engineering and quality control key parts of the process.

Key Components of Electro Mechanical Assembly

The process of electro mechanical assembly involves multiple components that come together to create a unified and efficient system.

- Printed Circuit Boards (PCBs)

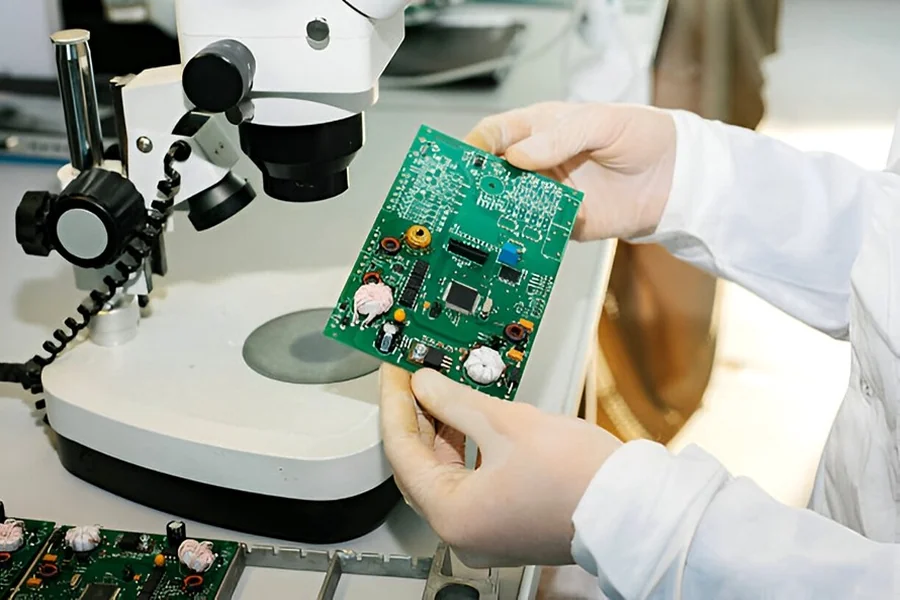

The PCB serves as the core of any electro mechanical product, housing microchips, capacitors, and resistors that control various functions. Proper design and assembly of the PCB ensure consistent electrical performance and signal reliability.

- Wiring and Cable Harnesses

Wiring harnesses connect different electrical components within the assembly. They ensure stable power and data transmission, minimizing electromagnetic interference and signal loss.

- Mechanical Enclosures and Frames

Enclosures protect the internal electronics from physical damage, dust, and moisture. They are designed using durable materials such as aluminum, stainless steel, or high-grade plastics to withstand harsh environments.

- Sensors, Motors, and Switches

These components enable motion and feedback within the system. For instance, motors drive mechanical movement, while sensors and switches provide feedback for automated control.

- Connectors and Fasteners

Precision connectors ensure stable electrical connections, while fasteners provide structural integrity to the entire assembly. Each must be selected based on application requirements and environmental conditions.

The Process of Electro Mechanical Assembly

The electro mechanical assembly process is a detailed and step-by-step integration that combines electronic and mechanical expertise.

- Design and Prototyping

The process begins with design and prototyping, where engineers develop detailed layouts and functional models. CAD and simulation software help visualize and optimize the product before production.

- Component Sourcing and Preparation

High-quality electronic and mechanical parts are sourced from reliable suppliers. Components undergo incoming inspection to ensure compliance with specifications.

- PCB Assembly and Integration

Once the PCBs are assembled, they are mounted into mechanical frames along with wiring and connectors. This step ensures perfect alignment and fit of all components.

- Mechanical Assembly

Motors, sensors, and mechanical structures are installed to complete the product’s mechanical framework. Precision tools are used to maintain accuracy during the build.

- Quality Testing and Validation

Every electro mechanical assembly undergoes functional, electrical, and environmental testing to confirm reliability. These tests ensure the final product meets operational and safety standards.

Applications of Electro Mechanical Assembly

The versatility of electro mechanical assemblies allows them to be used across diverse industries, including:

- Medical Devices: In diagnostic and surgical equipment where precision and reliability are life-critical.

- Automotive Systems: Used in electric vehicles, sensors, and control systems.

- Aerospace and Defense: For avionics, communication systems, and navigation equipment.

- Industrial Automation: Power control panels, robotics, and assembly line equipment.

- Consumer Electronics: Devices like home appliances and smart systems rely heavily on these assemblies.

Each application demands custom engineering and assembly processes to ensure long-term performance in varying environmental conditions.

Advantages of Electro Mechanical Assembly

Choosing a professional electro mechanical assembly solution offers several benefits that enhance product performance and business efficiency.

- Streamlined Production

Integrating electrical and mechanical processes under one system reduces assembly time and minimizes production errors.

- Improved Reliability

Properly assembled electro mechanical systems ensure consistent functionality even under heavy load or harsh operating conditions.

- Cost Efficiency

Consolidated design, manufacturing, and testing processes help lower overall production costs while maintaining quality.

- Enhanced Customization

Assemblies can be designed to fit specific requirements, making them ideal for specialized equipment and unique industrial applications.

- Simplified Maintenance

Well-organized cabling, modular design, and high-quality connectors make maintenance and future upgrades easier.

Quality Standards and Testing

To meet industrial and safety requirements, electro mechanical assemblies adhere to international standards such as ISO 9001, IPC-A-610, and UL certifications. Testing methods like thermal cycling, vibration testing, and electrical continuity verification ensure each product meets the expected durability and reliability benchmarks.

Manufacturers invest in automated inspection systems and skilled technicians to maintain consistency and precision in every production batch.

Conclusion

As technology continues to advance, electro mechanical assembly remains essential for industries that rely on integrated systems combining both electronic intelligence and mechanical strength. From concept to completion, precision in assembly ensures performance, safety, and reliability across applications.

If you are seeking a trusted partner to handle your complex assemblies, consider working with a company that offers expert PCB assembly services alongside full electro mechanical integration. Combining these capabilities ensures a streamlined production process, high-quality results, and reliable solutions tailored to your specific application needs.