The Microvia Circuit Board is one of the most advanced PCB technologies developed to support high-density interconnect (HDI) designs. As modern electronics shrink in size while becoming more powerful, traditional PCB designs face limitations in routing and connectivity. Microvia technology addresses these challenges by enabling compact, reliable, and high-performance designs. From smartphones and wearables to aerospace and medical devices, microvia boards are essential for today’s cutting-edge electronics.

What is a Microvia Circuit Board?

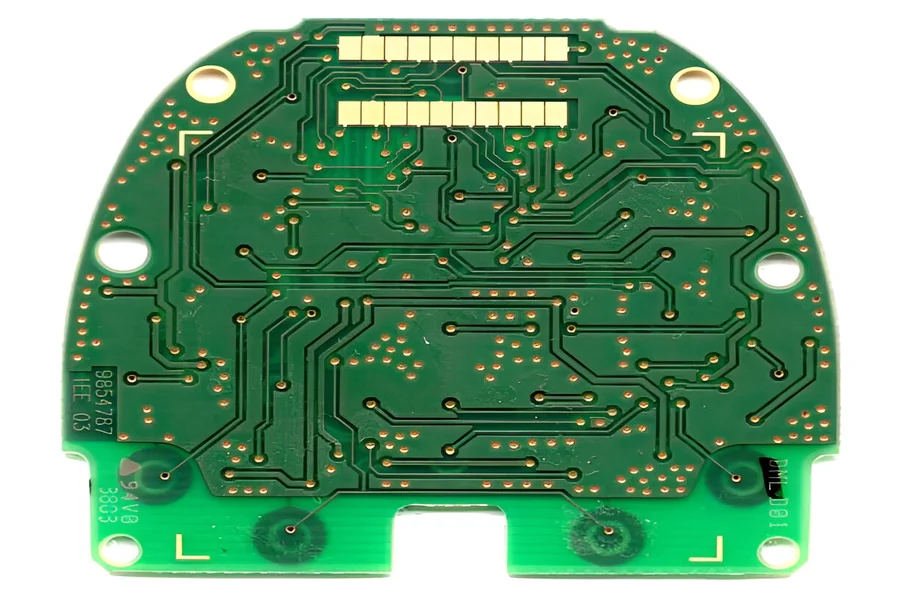

A Microvia Circuit Board is a type of HDI PCB that uses extremely small vias, typically less than 150 microns in diameter, to create connections between different layers of the board. These microvias are usually laser-drilled and plated with copper, ensuring strong electrical and mechanical connections. Unlike traditional through-holes, which extend through the entire PCB, microvias only connect adjacent layers, allowing for more routing flexibility and increased component density.

Characteristics of Microvia Circuit Board

Microvia boards are known for their compact design, precise interconnections, and improved electrical performance. The small vias reduce signal loss, minimize crosstalk, and enhance overall signal integrity, making them ideal for high-speed digital and RF applications. Additionally, microvias allow for multiple stacked or staggered configurations, further increasing routing density and design flexibility.

Importance of Microvia Circuit Boards in Modern Electronics

With the continuous miniaturization of electronic devices, manufacturers require boards that can fit more functionality into smaller form factors. Microvia Circuit Boards make this possible by maximizing available routing space and supporting advanced multilayer designs. This is particularly important in industries like telecommunications, automotive electronics, aerospace, and consumer electronics, where performance and space optimization are equally critical.

Applications of Microvia Circuit Boards

Smartphones and Mobile Devices

Microvia PCBs are extensively used in smartphones, tablets, and other portable devices due to their ability to support high-density circuits in compact designs.

Medical Devices

Medical equipment such as pacemakers, diagnostic tools, and wearable health monitors rely on microvia technology to deliver precision and reliability in small, lightweight packages.

Automotive Electronics

Advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle controls benefit from microvia boards that provide high-speed performance and durability under demanding conditions.

Aerospace and Defense

In aerospace and military applications, Microvia Circuit Boards ensure reliable signal transmission and compact design, meeting strict weight and performance requirements.

Advantages and Challenges of Microvia Circuit Boards

The advantages of microvia PCBs include enhanced signal integrity, reduced size, increased circuit density, and improved electrical performance. They also enable more compact and lightweight devices without sacrificing reliability. However, manufacturing microvia boards can be challenging due to their complexity. Precision laser drilling, advanced plating techniques, and strict quality control are necessary, which increases production costs. Despite these challenges, their benefits make them indispensable in advanced electronic design.

Future of Microvia Circuit Boards

The future of Microvia Circuit Boards is closely tied to the growth of 5G technology, artificial intelligence, and the Internet of Things (IoT). As demand for faster, smaller, and more reliable devices continues to rise, microvia technology will become even more critical. Advances in fabrication processes are expected to further improve efficiency, reduce costs, and expand the range of applications.

Conclusion

The Microvia Circuit Board represents a crucial innovation in modern PCB design, offering high-density interconnections, enhanced performance, and compact form factors. Its widespread use across industries highlights its importance in driving the future of electronics. For businesses seeking high-quality, precision-engineered solutions, working with an experienced Microvia Circuit Board Manufacturer ensures reliable performance and tailored designs that meet the most demanding requirements.